Introduction

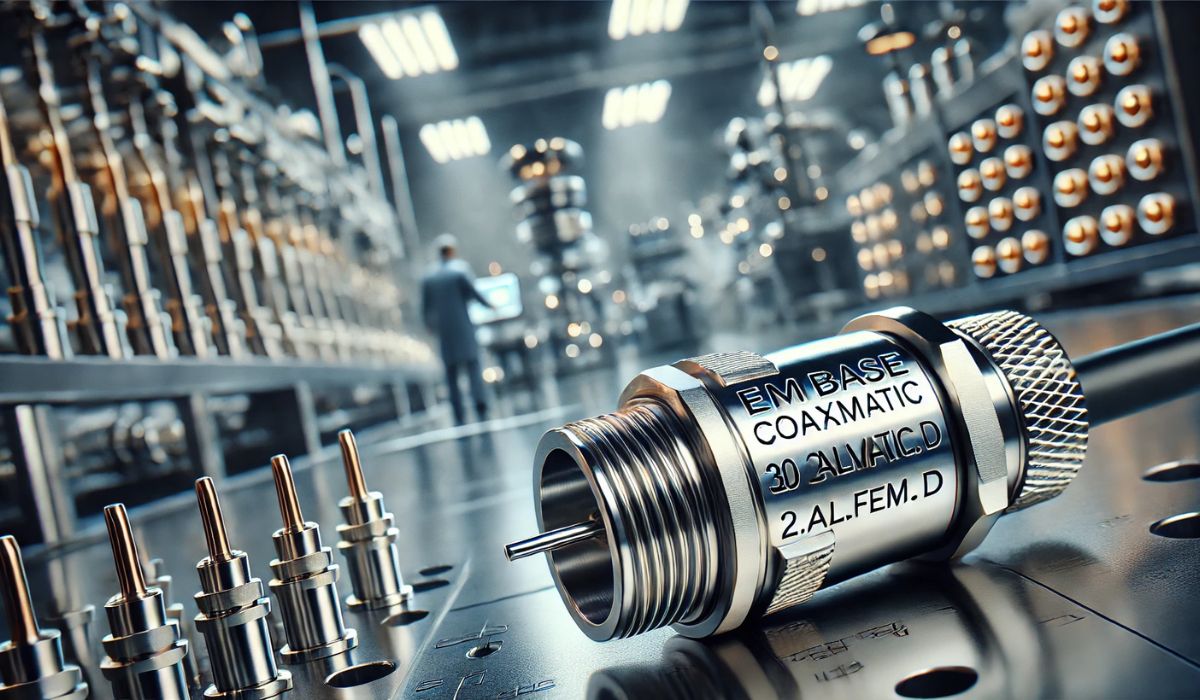

The Embase Coaxmatic 30 2ALV.FEM.D is a state-of-the-art cable processing system designed to revolutionize the way coaxial and multi-layer cables are handled. This innovative machine offers unmatched precision, ensuring that every cut, strip, and layer is processed to perfection. Designed for industries requiring high efficiency and reliability, the Coaxmatic 30 2ALV.FEM.D is setting new standards in modern technology.

Cable processing is a crucial component in industries like aerospace, telecommunications, and defense. The Embase Coaxmatic’s advanced features cater to these high-demand fields, making it indispensable. This article delves into its key features, applications, advantages, and more to help you understand why this system is a game-changer.

Key Features of Embase Coaxmatic 30 2ALV.FEM.D

Advanced Cable Processing Capabilities

The Embase Coaxmatic 30 2ALV.FEM.D excels at handling complex cable structures. Its ability to process multi-layered cables ensures versatility for various applications. Whether you’re dealing with coaxial cables or intricate fiber-optic configurations, this machine delivers consistent, high-quality results.

High Precision in Cutting and Stripping

Precision is critical when working with cables, especially in industries like telecommunications and aerospace. The Coaxmatic 30 2ALV.FEM.D uses advanced cutting and stripping technologies, minimizing errors and waste. This ensures your cables are prepared with exact specifications, improving operational efficiency.

Integration of Multi-Layer Cable Handling

This system can seamlessly handle multiple cable layers without compromising quality. It’s engineered to work with different materials, from copper to fiber, making it a one-stop solution for diverse industrial needs. This adaptability enhances its value across various sectors.

Compatibility with High-Frequency Applications

The Coaxmatic 30 2ALV.FEM.D is designed for high-frequency applications such as radar systems and satellite communications. Its precision and durability make it ideal for handling the specific requirements of these technologies, ensuring top-notch performance.

Applications of Embase Coaxmatic 30 2ALV.FEM.D

Use in Satellite Communication Systems

Satellite systems require precision and reliability, and the Coaxmatic 30 2ALV.FEM.D delivers both. Its ability to process cables for high-frequency transmissions ensures uninterrupted and clear communication, making it a preferred choice for satellite technology manufacturers.

Role in Radar System Installations

Radar systems depend on high-quality cables to operate effectively. The Embase Coaxmatic ensures that every cable meets strict industry standards, providing the accuracy and durability needed for radar operations. This reliability is especially critical in defense and aviation sectors.

Applications in Aerospace and Defense

In aerospace and defense, every component must meet the highest quality standards. The Coaxmatic 30 2ALV.FEM.D’s precise processing capabilities make it ideal for these industries. From manufacturing advanced avionics to creating robust defense systems, this machine plays a pivotal role.

Industrial Use for Coaxial Cable Production

For industries focused on mass-producing coaxial cables, the Embase Coaxmatic offers unmatched efficiency. Its ability to handle large volumes without sacrificing quality makes it an asset for industrial-scale operations, saving both time and resources.

Advantages of Using the Embase Coaxmatic 30 2ALV.FEM.D

Enhanced Productivity and Efficiency

The Coaxmatic 30 2ALV.FEM.D significantly boosts productivity by automating cable processing tasks. This reduces manual labor and speeds up production cycles, allowing industries to meet tight deadlines without compromising on quality.

Cost-Effectiveness for Large-Scale Industries

While the initial investment may seem significant, the long-term benefits of the Coaxmatic 30 2ALV.FEM.D outweigh the costs. Its efficiency and durability result in lower operational expenses, making it a cost-effective choice for industries handling large-scale cable production.

Superior Durability and Reliability

Built with high-quality materials, this machine is designed to last. Its robust construction ensures that it can handle demanding tasks without frequent breakdowns, providing reliable performance over extended periods.

Adaptability to Various Industries

The Embase Coaxmatic’s versatility makes it suitable for a wide range of industries. From telecommunications to defense, its ability to adapt to different cable types and applications enhances its value, ensuring it meets diverse industrial requirements.

Comparison with Other Cable Processing Systems

How It Stands Out in the Market The Embase Coaxmatic 30 2ALV.FEM.D shines in the cable processing industry due to its precision and advanced features. Unlike generic systems, this machine is tailored for high-frequency coaxial cables, ensuring unmatched accuracy. Its ability to process multi-layer cables makes it versatile, accommodating a variety of industrial needs. Furthermore, its user-friendly interface reduces the learning curve, enabling technicians to achieve optimal results with minimal training. Industries seeking reliable and efficient solutions find this system a top choice.

Key Differentiators in Performance and Technology This system outperforms competitors with its integrated multi-layer cable handling and high-speed operations. The precision in cutting and stripping surpasses industry benchmarks, ensuring consistent results. Its compact design coupled with robust technology enhances its adaptability to diverse environments. Additionally, the machine incorporates advanced diagnostics, minimizing downtime by identifying and resolving issues proactively. These features position it as a leader in cable processing innovation.

Competitive Analysis with Similar Models When compared to other cable processing systems, the Coaxmatic 30 2ALV.FEM.D offers a superior combination of speed, precision, and durability. While similar machines may focus on either speed or accuracy, this system excels in both areas. Its energy-efficient operation provides cost savings over time, a crucial factor for large-scale industries. Competitors often lack the advanced diagnostics and multi-layer capabilities, which makes the Coaxmatic 30 2ALV.FEM.D a preferred choice for demanding applications.

Technical Specifications

Dimensions and Weight The Embase Coaxmatic 30 2ALV.FEM.D boasts a compact design, measuring approximately 30 inches in length and 15 inches in width. Despite its robust capabilities, the system is lightweight, weighing around 25 kilograms. This design facilitates easy installation and mobility, making it ideal for dynamic industrial settings.

Voltage and Power Requirements Operating on a standard voltage of 220V, the system ensures compatibility with most industrial power supplies. It features energy-efficient mechanisms that optimize power consumption without compromising performance. The low power requirements make it a sustainable option for industries aiming to reduce operational costs.

Performance Metrics The Coaxmatic 30 2ALV.FEM.D delivers exceptional speed, processing up to 500 cables per hour, depending on complexity. It achieves a cutting precision of up to 0.01 mm, ensuring flawless results. These metrics demonstrate its capacity to handle high-volume tasks while maintaining superior quality, a critical requirement for industries like aerospace and telecommunications.

Industry Insights

Current Trends in Cable Processing Technologies The cable processing industry is moving towards automation and precision, driven by the need for efficiency and reliability. Machines like the Coaxmatic 30 2ALV.FEM.D embody these trends, offering advanced features that streamline operations. Industries are increasingly adopting such systems to meet the growing demand for high-performance coaxial cables, particularly in sectors like telecommunications and defense.

Industry Adoption of the Coaxmatic 30 2ALV.FEM.D This system has gained traction in industries requiring high-frequency applications, such as satellite communications and radar systems. Its adoption highlights the growing emphasis on quality and precision in cable processing. Companies leveraging this technology report significant improvements in productivity and operational efficiency, solidifying its reputation as a game-changer in the market.

Expert Opinions and Testimonials Experts praise the Coaxmatic 30 2ALV.FEM.D for its innovative design and reliable performance. Technicians note its ease of use and consistent results, making it a favorite in demanding environments. Testimonials often highlight its ability to handle complex tasks effortlessly, proving its value across various industries. These endorsements reinforce its status as a trusted solution.

Maintenance and Operational Tips

How to Ensure Optimal Performance To maintain peak performance, operators should follow the recommended maintenance schedule and inspect the system regularly. Keeping the machine clean and free of debris is crucial to avoid malfunctions. Lubricating moving parts periodically ensures smooth operation and extends the system’s lifespan.

Common Issues and Troubleshooting While the Coaxmatic 30 2ALV.FEM.D is highly reliable, occasional issues may arise. Common problems include misaligned cables or dull cutting tools. Operators can resolve these by realigning the cables or replacing worn tools. The system’s diagnostic features provide clear alerts, simplifying troubleshooting and minimizing downtime.

Recommended Maintenance Schedule Routine maintenance should be performed weekly, including cleaning and inspecting all components. Monthly checks should focus on tool sharpness and system calibration. Annual servicing by a certified technician ensures the machine continues to deliver top-tier performance, preventing costly repairs in the long run.

FAQs

What Industries Benefit Most from This System? I

ndustries such as telecommunications, aerospace, and defense benefit significantly from this system. Its precision and ability to handle high-frequency applications make it ideal for manufacturing coaxial cables used in these fields. Additionally, automotive and electronics sectors leverage its capabilities for complex wiring projects.

Is It Suitable for Small-Scale Operations?

Yes, the Coaxmatic 30 2ALV.FEM.D is versatile enough to accommodate both small-scale and large-scale operations. Its user-friendly design and energy-efficient performance make it accessible for businesses of all sizes. Small-scale operators can also take advantage of its low maintenance requirements and durability.

How Does It Handle High-Frequency Applications?

The system’s advanced technology ensures precise handling of high-frequency coaxial cables. Its multi-layer processing capability allows it to produce cables that meet the stringent requirements of applications like satellite communications and radar systems. This reliability makes it a trusted choice for critical projects.

What Are the Warranty and Support Options?

The Coaxmatic 30 2ALV.FEM.D comes with a comprehensive warranty covering parts and labor for up to two years. Manufacturers also offer extended support plans, including regular updates and access to a dedicated technical support team. This ensures users have the assistance they need to maximize the system’s performance.

For More More Visit: Creative Blogs